On November 15th, the 2022 German Formnext exhibition opened in Frankfurt. After three years of absence, eSUN returned to the “international stage” of the additive manufacturing industry. New materials, new technologies, new applications… Countless industry-leading innovations and designs appeared here, attracting many visitors.

At this exhibition, eSUN also brought the latest research and development achievements and comprehensive industrial solutions. Among them, fast series solutions have become one of the focuses of the whole audience.

eSUN Fast 3D Printing Materials

The advantages of 3D printing in small-scale customization are unparalleled, but its printing speed is not fast enough and its efficiency is not high, which has been criticized by users. Previously, it usually took several hours to print a model, and it may take more than ten hours or even several days to print some models with complex structures and large volumes. With the development of new materials and technologies, the introduction of more efficient fast printing solutions not only meets the needs of users, but also conforms to the development trend of the industry.

In this process, the acceleration of 3D printers is on the one hand, and the coordination of materials is on the other hand. Only by combining the two, can we provide users with a better use experience.

The model printed with eSUN fast PLA (ePLA-HF) has high surface quality and good detail performance. At the same time, the material has excellent printability and good adaptability. By adjusting the material production process, the dependence of fast printing on the cooling power of the printer can be reduced. During high-speed printing, it is smooth and fast cooling without deformation. Ordinary filaments can only be printed below 100mm/s, while eSUN fast PLA (ePLA-HF) can print at 250mm/s, and can maintain better printing effect than other materials at this speed.

At the same time, after testing, eSUN PLA+ materials also have excellent high-speed printing performance. Welcome to try!

iSUN3D Customized Orthotic Insole System

ISUN3D customized orthopedic insole system is a mature application case developed by eSUN based on flexible TPU 3D printing materials and 3D printing technology in the field of foot rehabilitation medicine. At the exhibition site, the system has also attracted many visitors to experience.

It should be mentioned that this year, eSUN and WANHUA Chemical released eTPU Antimicrobial TPU material, which has excellent antibacterial and antifungal effects. At the same time, through the balance of flow temperature and viscosity, this antibacterial TPU material can also give consideration to strength and formability, and maintain good performance under high-speed printing while maintaining high fluidity.

Gather Passion and Meet New and Old Friends

During the four-day exhibition, eSUN received many 3D printing makers, teams and manufacturers from various regions. They fully communicated with each other about the current products and development plans of eSUN, watched the materials and models for the exhibition, and exchanged the development trend and future of the industry. The scene was professional, lively and warm.

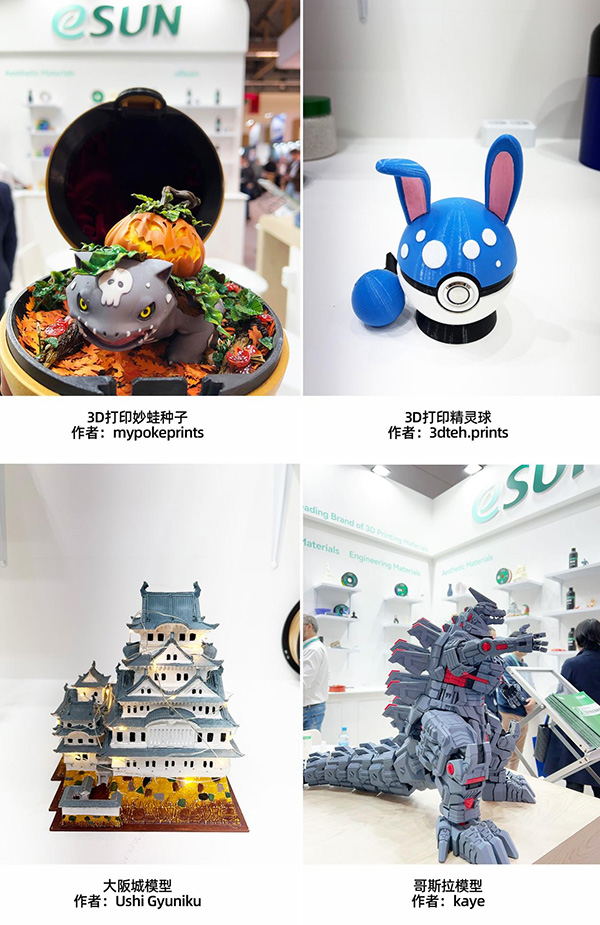

Here, I would also like to thank the 3D printing makers at home and abroad who sponsored the models for eSUN, and thank you for your trust and support. These models on display have also been loved by many visitors.

In the context of the normalization of global epidemic, in the future, eSUN will more actively participate in overseas exhibitions, seminars and other offline activities! Next stop, we are going to CES - Consumer Electronics Show in Las Vegas, USA!

Reprinted from: eSUN